Pharmaceutical Development

Pharmaceutical Technology

- Dry blending

- Wet granulation: 1) Fluid Bed technologies; 2) High shear mixer

- Extrusion granulation

- Tablet compression

- Capsule filling

- Oral solutions/suspensions and emulsions

- Semi-solid (cream, gel, ointment)

- Sterile liquid injectable

- Freeze-dried forms

- Nasal sprays

- Ophthalmics mono-dose or multi-dose preservative free

- Formulations from immediate release to extended release/slow release formulations

- Drug delivery formulations

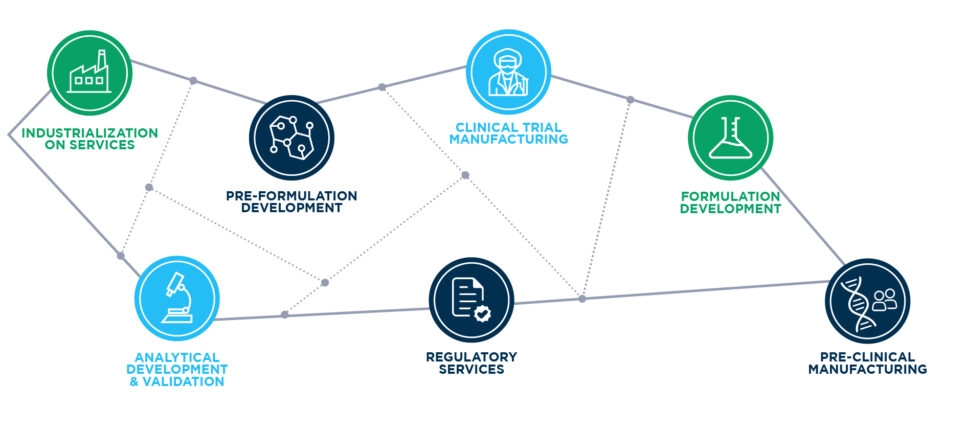

Pre-formulation Development Services

Initial Risk Assessment:

- Regulatory strategy and patent review.

- Sourcing constraints

- Quality by Design approach: preliminary design of Quality Target Product Profile (QTPP) and Critical Quality Attributes (CQA) to consider (drug substance and drug product)

- API physical-chemical characterization (Particle Size Distribution, Enantiomeric forms, Polymorphism)

- Excipients and packaging materials selection

- Compatibility studies between API and excipients

- Reverse engineering studies from existing products (where applicable)

- Toxicology assessment and substance categorization

Formulation Development Services

- Formulation optimization and manufacturing of small batches for toxicological animal studies

- Prototype generation and Design of Experiments (DoE)

- Design of qualitative-quantitative formula. Definition of QTPP and CQA

Investigational Medicinal Product (IMP)

- Manufacturing, labelling, packaging and release of IMP and placebo

- Support on the preparation of the Investigational Medicinal Product Dossier (IMPD)

- Support on the design of clinical BE studies.

Industrialization Services

- Manufacturing Process Development and Critical Process Parameters (CPP) Definition

- Scientific and technical support on scale-up and engineering batches prior to full scale validation/registration batches to Third Manufacturers

- eCTD services like authoring, validating and e-publishing submissions in eCTD formats.

- Tech Transfer Out

Analytical Development Services

- Analytical Method Development and Validation for Drug Substance and Drug Product

- Analytical Method Development and Validation for Impurities, Related Substances and Preservatives

- Extractable & Leachable studies

- Forced degradation studies

- Comparative In Vitro Dissolution Tests

- In vitro – In vivo studies

- Pre-stability and ICH stability studies

- Analytical Method Development and Validation

- Validation of microbiological methods

- In vitro Release testing (IVRT)

- ICH for zone II, IVa , IVb, US&EU, semi permeable products. Stability Chambers housing.

- Consulting Services (eg. GAP, Training, Audit)

Regulatory Services

- Advice on regulatory registration strategy

- Advice on CMC issues related development stages, manufacturing, quality control release testing,

- Specifications and stability of the product

- Nitrosamines risk assessment and ICH Q3D elemental impurities

- Toxicology assessment of NCE, PDE

- Advice on clinical issues related to manufacturing of IMP

- Support on the preparation of the Common Technical Dossier (CTD)

- Support on the preparation of the Investigational Medicinal Product Dossier (IMPD)

- Preparation of answers to Regulatory Bodies

HPAPI Products

A dedicated area for non-GMP studies including High Potent APIs (HPAPI) suitable for:

- Manufacturing of batches for toxicological studies in animal models

- Formulation trials at lab scale

- Design of experiments

A new dedicated area will be able to work under GMP conditions Safebridge 3A HPAPIs and suitable for:

- Manufacturing of Investigational Medicinal Product Phase I/II

- Comparability studies

- GMP DoEs in lab scale

Small Scale GMP Manufacture

A new GMP Pilot Plant will be fully operational in 2022 and suitable for:

- Manufacturing of small commercial batches of Speciality Drugs

- Manufacturing of Investigational Medicinal Products for Phase II/IIl (HiPo and Non HiPo)

Consumer Care Development

Initiation of the Development

- Customer Orientation, Key Concepts, Positioning

- Product Categorization, Market Analysis

Formulation Development

- Regulatory Requirements, Compliance, QTTP

- Safety, Technical, Regulatory data documentation for raw materials

- Formulation Development, Literature Research, Laboratory scale prototypes,

- ICH Stability, Pre-Safety Toxicological Assessment, CQA

- Packaging Development

- Analytical Methods Development

- Microbiological Methods Development

- Development Report

Product Development

- Definition of QTPP and CQA, Finalization of Formula

- Process Optimization

- GMP scale-up Production, Filling, ICH Stability, Compatibility

- Clinical Studies, Safety Studies, Efficacy Studies

- Technical File, PIF initiation

Planning & Production

- Support on Industrial Validation Batch Production, Filling

- Industrial Validation Batch ICH Stability

- Analytical Method Validation

- Microbiological Methods Validation

Product Release to Market

- Technical File Support | PIF completion

- Transfer Out activities (if applicable)